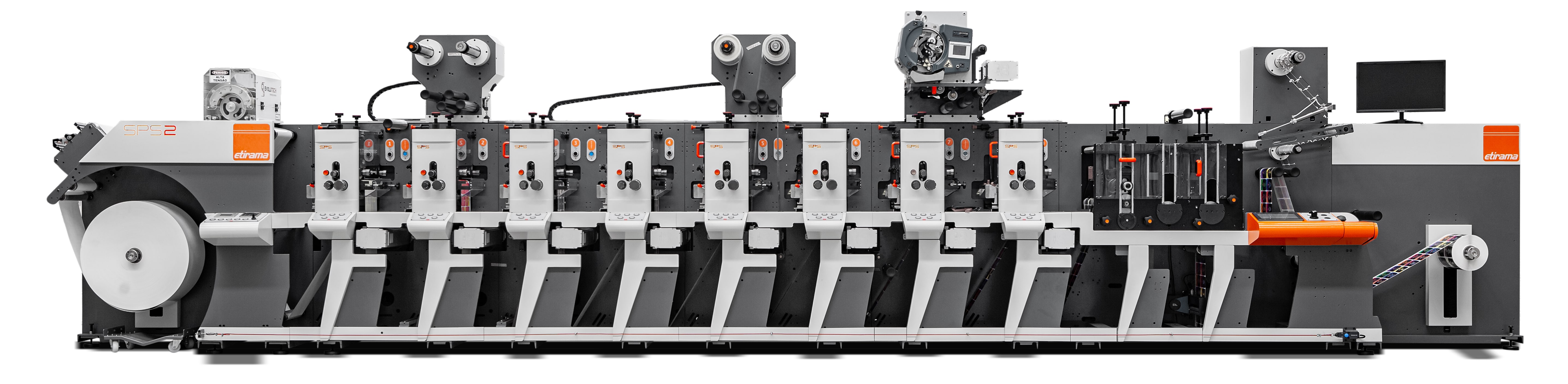

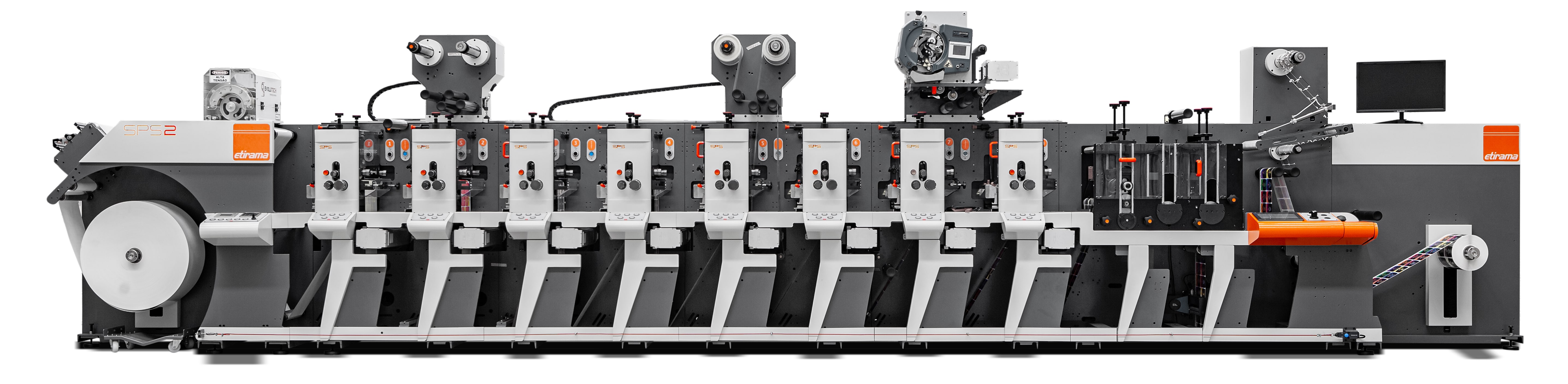

Servo Driven Flexo Press ETIRAMA SPS2

Configuration

- High-Performance Servo Driven Flexo Press

- UV Drying System

- Hot Air Dryers with Temperature Control

- Equipped with up to 10 Print Stations

- Print Speed up to 150 m/min

- Print width 350mm

- Bobbin Capacity up to 800mm Diameter (unwinder/rewinder)

- DELAM-RELAM (impression on adhesive)

- Web Turn Bar

- Triple Die Cut Station with 2 Rotary Die Cut Cylinders

- Video Camera by German brand BST

- COLD Stamping

- UV Lamination

- CAST AND CURE

- Sheeter (conveyor) with Automatic Counter

- Corona Treater for Substrates (1 Face), Brand Corona Fix

| Print width | Max. 350mm / Min. 200mm |

| Maximum substrate width | 360mm |

| Maximum mechanical speed (1) | 150 meters/minute |

| Maximum number of print stations | Up to 10 units |

| Gear type in print stations | Helical CP 1/8″ (DP 26) |

| Minimum dimensions of plate cylinders | Z 70 (222.25mm / 8.75″) |

| Maximum dimensions of plate cylinders | Z 160 (508mm / 20″) |

| Minimum dimensions of die cut cylinders | Z 70 (222.25mm / 8.75″) |

| Maximum dimensions of die cut cylinders | Z 160 (508mm / 20″) |

| Maximum diameter of waste bobbin | 800mm (31.49″) |

| Maximum coil dia of unwind and rewind | 1,000mm. |

| Compressed Air | 6~8 bar with 25,000 l/h 15 PSI |

| Voltage requirements (3) | 380V – 3 phases (+/- 5%) |

| Voltage frequency | 50 Hz (+/- 2%) |

| Altitude | Max. 2,000 meters above sea level |

| Room temperature | 10°C to 25°C (50°F to 77°F) |

| -Humidity | 30% to 80% (at 20°C / 68°F) |

| Applications | PSS labels, Papers and Light Carton (min. 20 microns – max. 300 microns)s |