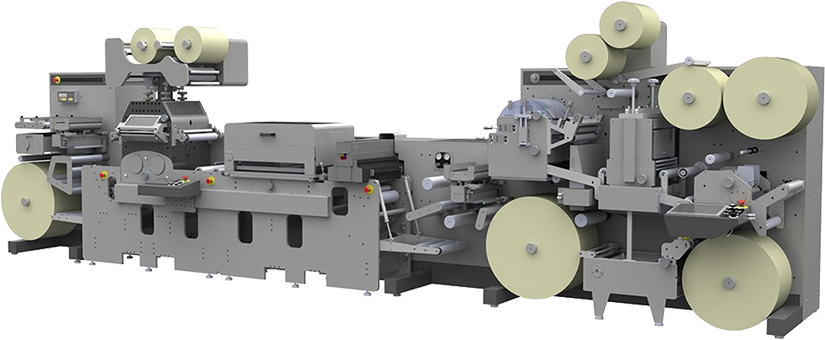

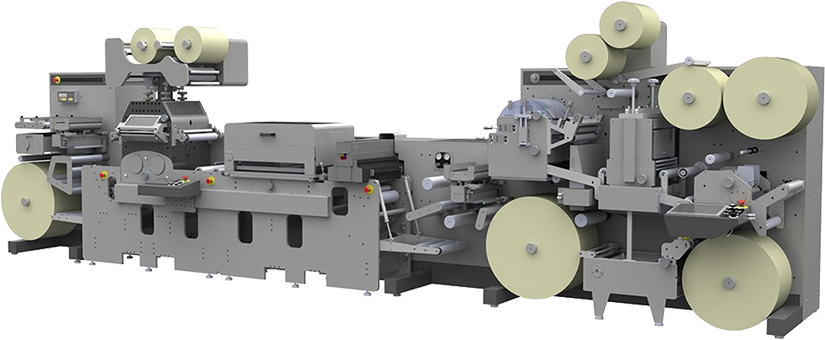

DC330FB Combination Print Finishing

DC330FB Combination Print Finishing

The powerful combination of semi-rotary die cutting, flatbed screen-printing and a 30 ton pressure heavy duty stamping and hot foil unit, makes even complex labels easy to run. The tooling cost is very low and most tools can be made locally or in-house. Existing tooling for older flatbed equipment can be reused. If you disable the flatbed units, the line cab produce normal industrial labels with flexo, lamination, cold foiling and semi-rotary die cutting at up to 45 m/min ( can be increased to 65 m/min with Productivity Pack).

Characteristics

High pressure flatbed hot stamp module

The first module on the line is a flat bed hot stamp module. The module has a pressure of 30 t. The servo drive system ensures equal pressure and impression time at all speeds. A built-in foil saver minimizes running costs. As standard the unit is fitted with a foil tower for cross & along web operation. The foil tower allows embossing and foiling to be processed in one step. Plates can be changed in the hot state due to a smart “slide-out” plate loading design.

Screen unit with servo drive

When raised varnish, Braille or decorative surfaces are needed – screen print is the key. The traditional flatbed design makes local tool (mesh) manufacturing possible. With a small in-house kit, new screens can be ready at short notice. This fits ideally with digital print and day-to-day delivery. The unit is equipped with a powerful air cooled UV lamp with electronic power control from 20 – 200 W/cm.

Flexo graphic varnish and cold foil

The optional flexo printing station provides flood varnish, spot varnish or UV glue for cold foil. There is an optional pack of 14 cylinders making it easy to fit every spot job. The foil tower can be used for UV lamination, super gloss and super matte effects as well. Curing is done with a 20 – 200 W/cm air cooled UV lamp. Having flexo varnish is a must for proper scratch protection of digitally printed labels.

Semi-rotary die cutter

The die cutting station is digitally and servo driven. As standard a 25” cylinder is included offering a cutting range of 2” – 22”. The system has a built-in dispro feature that allows plates from existing machines to be reused on the GM unit. Cutting depth can be set via an optional K&B GapMaster unit. The die cutter can operate in semi-rotary or full rotary mode.

Options

- Corona system.

- Automatic knifebox.

- Ink pumps. Gap-master.

- Inspection system.

- Various shaft sizes.

Technical Specifications

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 – 330 mm | 2 – 13” |

| Substrate | 50 – 200 µm | |

| Flatbed | ||

| Stamp plate | Up to 6500 imp/min | |

| Screen frame | Up to 4000 imp/min | |

| Stamp plate | 330 x 304,8 mm | 13 x 12” |

| Screen frame | 660 x 500 x 30 mm | 26 x 19.7 x 1.2″ |

| Print area | 330 x 330 mm | 13 x 13″ |

| Die Station | ||

| Semi-rotary speed | 45 m/min (65*) | 148 ft/min (213*) |

| Full-rotary speed | 72 m/min | 236 ft/min |

| Die plate size (repeat) | 50 – 558,8 mm | 2 – 22” |

| Rewinder | ||

| Diameter max | Ø500 mm | 19.7″ |

| Core diameter | 25 – 152 mm | 1 – 6″ |

| Unwinder | ||

| Diameter max | Ø700 mm | 27.6” |

| Core diameter | 76,2 or 152,4 mm | 3 or 6″ |

| Flexo Station | ||

| Print cylinder size | 228 – 482,5 mm | 9 – 19″ |

| Spot varnish option (digital sensor register control) | ||

| Slitting Station | ||

| Knife Type | Pneumatic crush, shear or razor knife | |

| Power / Air | 3x400V+N+PE, 63A, 6 bar | |

| Size (WxDxH) | 6,8 x 1,3 x 2,0 m | |

| Exhaust | Ø160 mm, 2×800 m³/h. Outside. | |