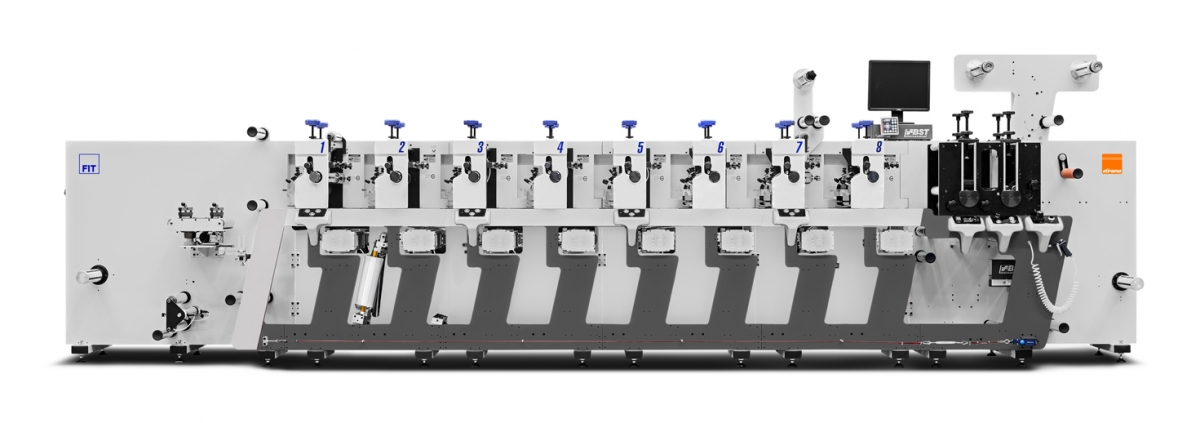

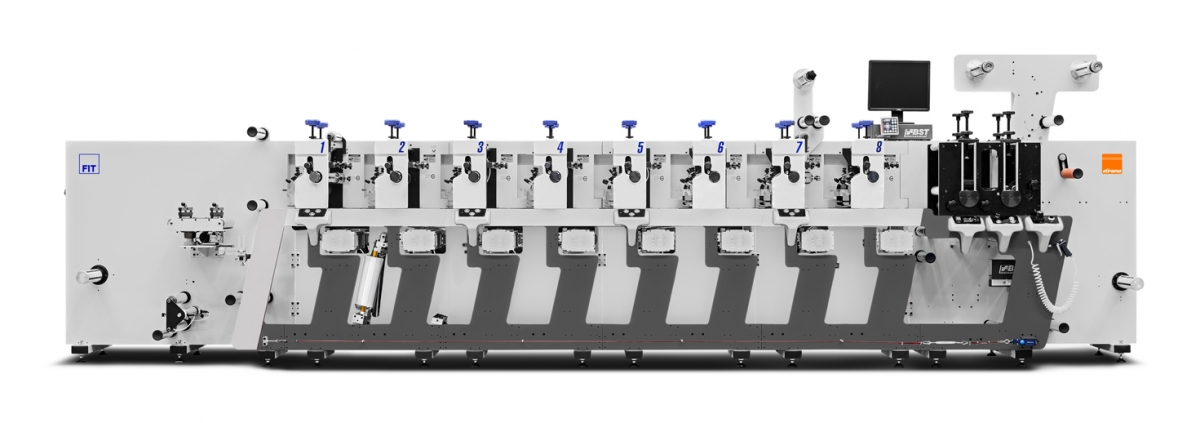

Etirama Fit – Amazing Label Press

Configuration

- Maximum number of print stations: 10 colors

- Maximum print width: 250 mm or 350 mm

- Maximum mechanical speed: 100 m/min

- UV curing system

- Hot air drying between colors

- Unwind/ Rewind mandrels for bobbins up to 800mm

- Automatic tension control

- Splice table

- Electronic web guide, German brand BST

- Delam-relam

- Web turn bar

- Automatic plate cylinders throw-off

- Cold stamping (UV Lamination)

- Video Scan, German brand BST

- Double die-cut station

- Sheeter with conveyor

| Print width | Max. 350mm / Min. 200mm |

|---|---|

| Maximum substrate width | 360mm |

| Maximum mechanical speed (1) | 100 meters/minute |

| Maximum number of print stations | Up to 10 units |

| Gear type in print stations | Helical CP 1/8″ (DP 26) |

| Minimum dimensions of plate cylinders | Z 70 (222.25mm / 8.75″) |

| Maximum dimensions of plate cylinders | Z 136 (431.8mm / 17″) |

| Minimum dimensions of die cut cylinders (2) | Z 70 (222.25mm / 8.75″) |

| Maximum dimensions of die cut cylinders | Z 136 (431.8mm / 17″) |

| Maximum diameter of waste bobbin | 600mm (23.5″) |

| Diameter of unwind & rewind mandrels | 3″ (76mm) |

| Compressed air | 6~8 bar with 25,000 l/h |

| Voltage requirements (3) | 380V – 3 phases (+/- 5%) |

| Voltage frequency | 50 Hz (+/- 2%) |

| Altitude | Max. 2,000 meters above sea level |

| Room temperature | 10°C to 25°C (50°F to 77°F) |

| Humidity | 30% to 80% (at 20°C / 68°F) |

| Room temperature | 10°C to 25°C |

| Humidity | 30% to 80% (at 20°C) |

| Applications | Aluminum foils (min. 20 microns) |