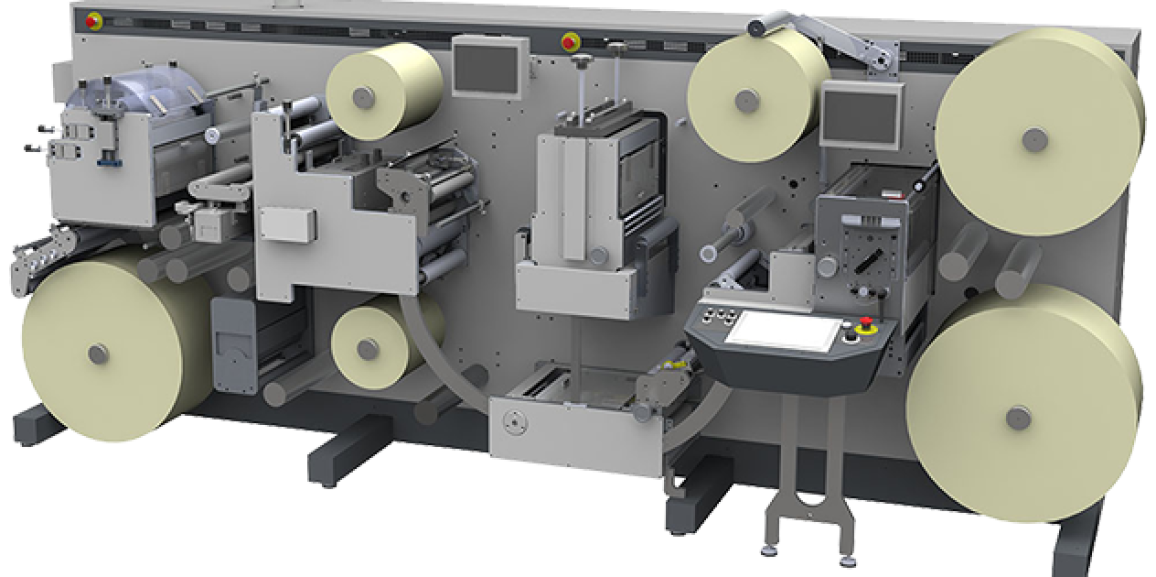

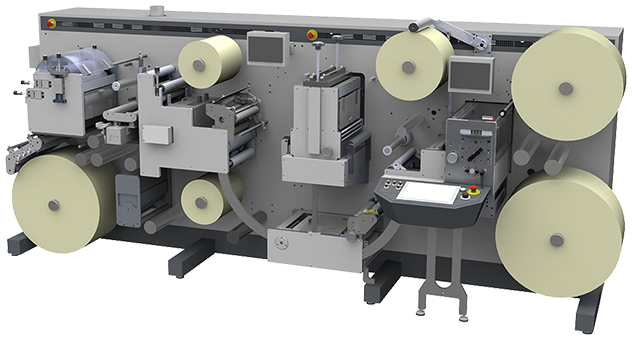

DC330 Semi-rotary Label Finishing

DC330 Semi-rotary Label Finishing

GM’s DC series has been in the market for the past 15 years. All DC’s are prepared for both offline and inline operation with a digital press. The inline interface includes remote start, stop and pause of the digital press from the DC’s touch screen. The lines come with a number of options; laser die cutting, hot and cold stamping, screen printing, automatic knife box, 100% inspection, web-to-sheet mode (conveyers) and more. As standard, the machine operates in blank label mode, full rotary mode, semi-rotary mode and re-register mode for digital finishing.

Option

- Laser die cutting unit.

- Automatic knife box that sets the knifes in seconds.

- Buffer for inline operation 48 meters of storage.

- Peel and reveal (multi layer labels).

- RL14 roll lifter.

- Lamination station.

- Spot varnish (Servo registration system for spot varnish / glue / cold foil including roller).

- Sleeve 9 – 19” for Flexo station.

- Splice table.

- Back scoring module (easy waste matrix pickup).

- Waste compression roller.

- Extra rewind spindle.

- Ink pump.

- Hot air dryer (11.6 KW).

- External 1000mm / 200kg jumbo unwind.

- Shear knife station with 3 knives, max. 16 (replaces crush knife station).

- Extra Flexo varnish with UV system.

- Extra full-rotary die station (for die cut or embossing).

- Extra semi-rotary die station (for die cut or embossing).

- Flatbed hot foil station with foil saver.

- Corona treater.

- GapMaster PLUS.

- Conveyer system for sheet die cutting.

- Small external conveyer Stacker for conveyer.

- Screen printer.

- Sheet output module.

- Extra die station.

The DC330 can be fitted with the ETV330/515 High Speed Sheeter to make “label sheets” – see a demonstration of this configuration here:

In register lamination unit for multi layer / peel and reveal labels. This module is a great value adding feature for the DC330. Multi-layer units sell at much higher prices compared to normal labels. The unit is a fraction of the size of a conventional solution with turn bars and cross over units. This is truly the optimal solution for digitally printed multilayer labels.

Another popular option is the laser die module. This offers “tool free” laser die cutting. Day to day delivery of digital printed labels. See an example here:

Characteristics

As digital label printing continues to grow, label-printing houses are realizing the need for all-inclusive digital printing systems that provide value-added features for producing fully finished labels. The DC330 from Grafisk Maskinfabrik offers the ideal solution. A complete converting and finishing unit, this product was specially created for use with digital printing presses. The DC330 can be set up as an in-line extension to a digital label printing system, allowing the web to continue directly into the converter from the digital press. It can also be used as an off-line converting and finishing unit for jobs from other digital presses or conventional presses. It can even function as a printing press for specialized value-added solutions.

The DC330 can be equipped with job-automation and configured to work with industry standards (ESKO, CERM, LabelTrax, XML, SQL). Job data can be stored in the machine and re-called with a bar-code reader.

The GM DC330 integrates the most advanced converting and finishing techniques available today. When used together with the a digital label press, this innovative unit gives professional label printers a complete and versatile solution for high-volume digital printing.

Modular platform for added flexibility

Customizable to fit your needs, depending upon the specific application

Precision cutting to reduce waste

Print-to-cut registration in just one rotation no station; no station movement or mechanical setup required; semi and full-rotary die cutting

Speed and versatility

Adjustable repeat lengths from 2” – 21”; line speeds up to 50 meters per minute

Varnish finishing options

UV flexo varnish station with registration; SUPERgloss varnish capabilities

Servo-driven web tension control

Ensures accurate processing over a wide range of substrates

Fully customizable and upgradeable

Multiple options available to customize your system

Easy web access and maintenance

Cantilevered design

Technical Specifications

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 50 – 330 mm | 2 – 13” |

| Substrate | 50 – 200µm | |

| Die Station | ||

| Semi-rotary speed | 50 m/min | 164 ft/min |

| Full-rotary speed | 72 m/min | 236 ft/min |

| Die plate size (repeat) | 50 – 558,8 mm | 2 – 22” |

| Rewinder/Unwinder | ||

| Max. internal unwind | Ø700 mm | 27.6” |

| Max. single or dual shaft rewind | Ø500 mm | 19.7” |

| Core diameter | 76,2 or 152,4 mm | 3 or 6” |

| Laser Die | ||

| Power | 100, 150, 250 or 400W | |

| Laser Type | Single head pulsed CO2 | |

| Laser Spot Size | 350 μm | |

| Flexo Station | ||

| Print Cylinder size | 228 – 482,6mm | 9 – 19” |

| Spot varnish option (digital sensor register control) |

||

| Slitting Station | ||

| Knife Type | Pneumatic crush, shear or razor knife | |

| Minimum distance crush | 12,7 mm | 0.5” |

| Minimum distance shear | 10 mm | 0.4” |

| Power/Air | 3x400V+N+PE, 32A, 6 bar | |

| Size (WxDxH) | 4,0 x 1,3 x 1,7m | |

| Exhaust | Ø100mm, 800m3/h. Outside. | |