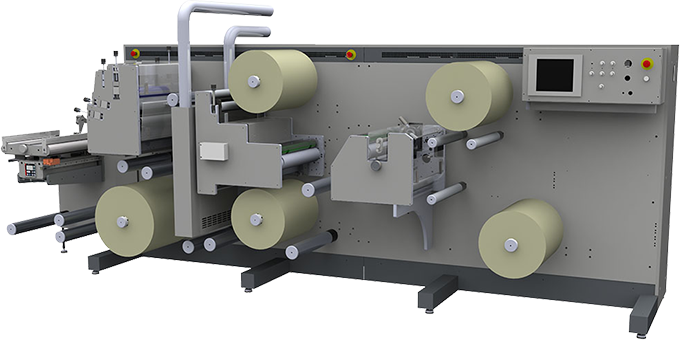

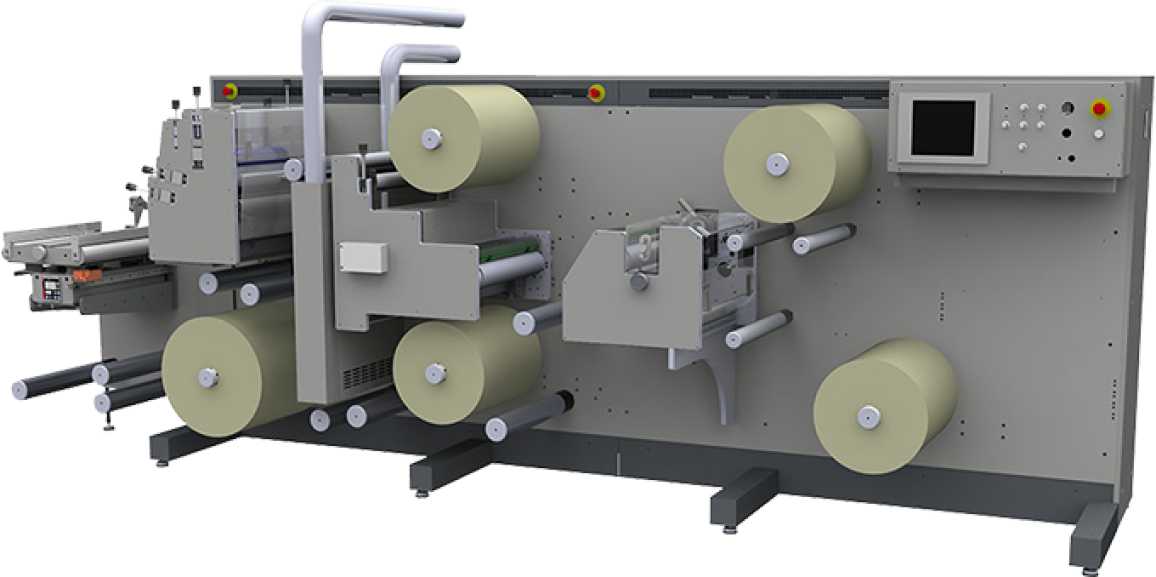

UC500 Coating and priming unit

The UC500 coating line is a universal coating/priming unit. It comes as an inline or offline version. Inline versions support all major digital presses. GM delivers the UC500 in both left- right and right-left run direction. Coatings are applied with a flexo graphic station and can be both UV and water based. The UC500 can be equipped with partial varnish, lamination, super gloss and other coating options. For priming synthetics a Corona system is needed. Water based coatings will need a closed chamber option in most cases. The UC500 can be delivered in a “full duplex version” that applies coatings to both sides of the web. The standard 4×1.6 meter UC500 has a more compact sister; The ultra compact UC500L. This light version measures only 2×1.6 meters.

Characteristics

The converting line consists of a UV varnish, lamination/supergloss with length slitting.

Operation can be both inline with a dancer or offline (optional unwind module).

Typical applications are banners, folders, post cards and roll-to-roll printed labels (not die cut).

The line is operated by a touch display and available for web widths of 330mm (~13.0”) or 515mm (~20.3”). The machine can be supplied with rotating length slitting.

Advantages

- UV flexo varnish.

- Ultrasonic web guide.

- Pneumatic 76mm spindles.

- Dual 76mm rewind with Ø500mm capacity.

- Optional hot-air for aqua varnish.

- Touch display setting of label quantity per sheet and other job information.

- Automatic register control adjusts for changes in the web speed (cut to mark).

Optional equipment

- Length slitting knives (rotary top and bottom cutter) max. 6 knives. (Also for retrofitting).

- Separate unwind section, max. roll diameter 1000mm (~39.4”).

- Hot-air module for Aqua varnishJogger table for sling stacking.

- Spot varnish.

- Corona treater.

- Back scoring / Perforation.

Technical Specifications

| Specifications | Metric | Imperial |

|---|---|---|

| Web width | 100 – 500 mm | 4 – 20″ |

| Substrate | 60 – 200 µm | |

| Rewinder | ||

| Diameter max. | Ø500 mm | 19.7″ |

| Core diameter | 76,2 or 152,4 mm | 3 or 6″ |

| Unwinder | ||

| Diameter max. | Ø700 mm | 27.6″ |

| Core diameter | 76,2 or 152,4 mm | 3 or 6″ |

| Flexo Station | ||

| Orint cylinder size | 228,6 – 482,6 mm | 9 – 19″ |

| Curing | GEW UV 6 kW | |

| Spot varnish option (digital sensor register control) | ||

| Hot air drying system | 11 kW | |

| Power / Air | 3x400V+N+PE, 16A, 6 bar | |

| Dimensions (WxDxH) | 3,8 x 1,5 x 1,7 m | |

| Exhaust | Ø100 mm, 800 m³/h. Outside | |